-

Products

-

-

Technical Services

-

Product Usage Precautions

| 1. During assembly, pay attention to the size of the core and the tolerance fit with the transmitter housing. It is recommended to process the SMP2100 core assembly cavity to 19+0.05+0.02 to achieve the required gas tightness. |

| 2. During assembly, ensure it is placed vertically and apply even pressure to prevent jamming or damaging the compensation piece. |

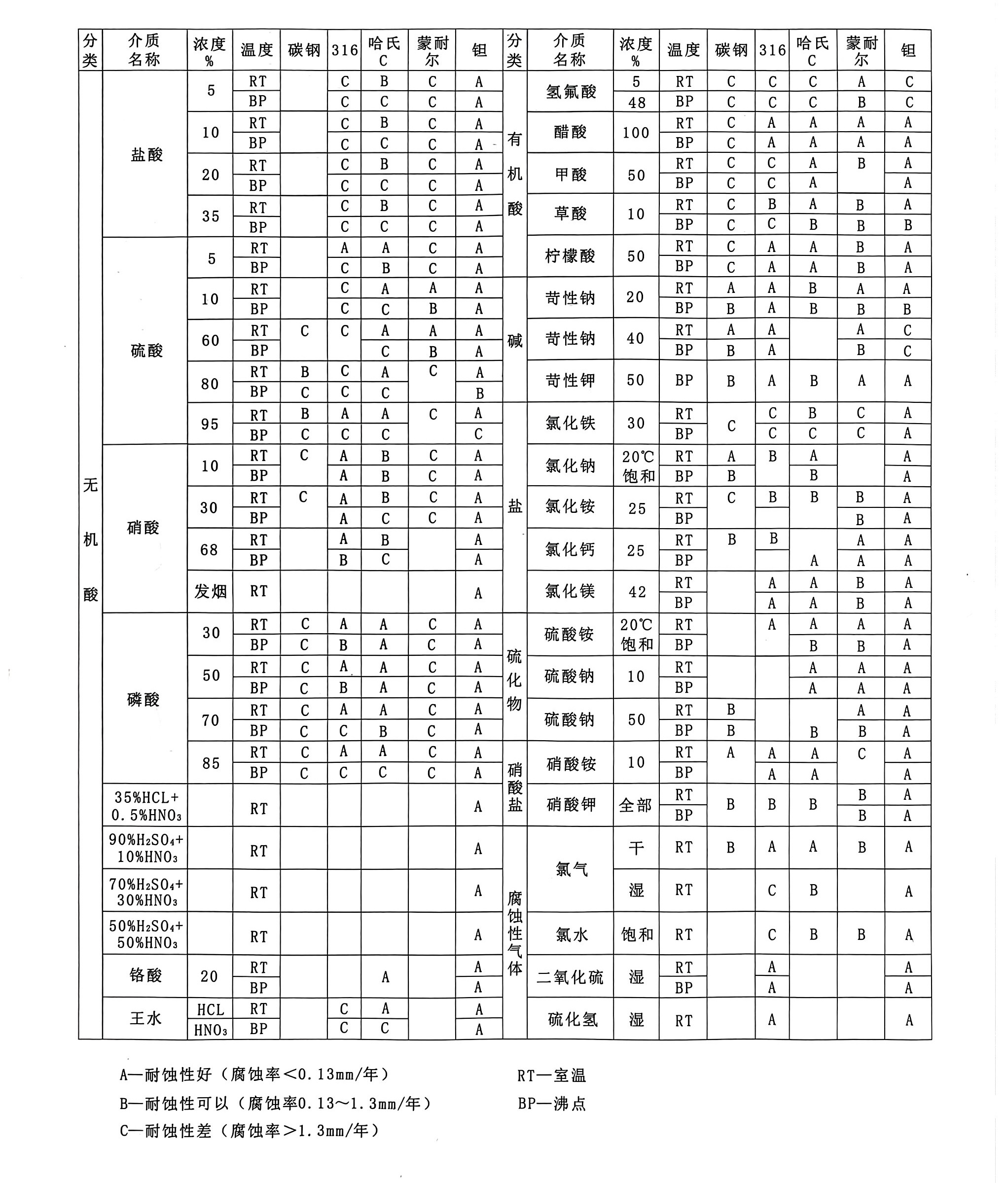

| 3. The measured medium must be compatible with the core diaphragm housing material (316L); otherwise, special instructions must be provided when ordering. |

| 4. Do not press the sensor diaphragm with hands or hard objects to avoid damage to the core due to chip deformation or perforation. |

| 5. When wiring, the core pins should not be cut too short, generally not less than 5mm, and the welding time should not exceed 5 seconds. |

| 6. The vent pipe at the rear of the G-type core must remain open to the atmosphere. |

| 7. It is prohibited for water, water vapor, or corrosive media to enter the reference chamber at the rear of the core. |

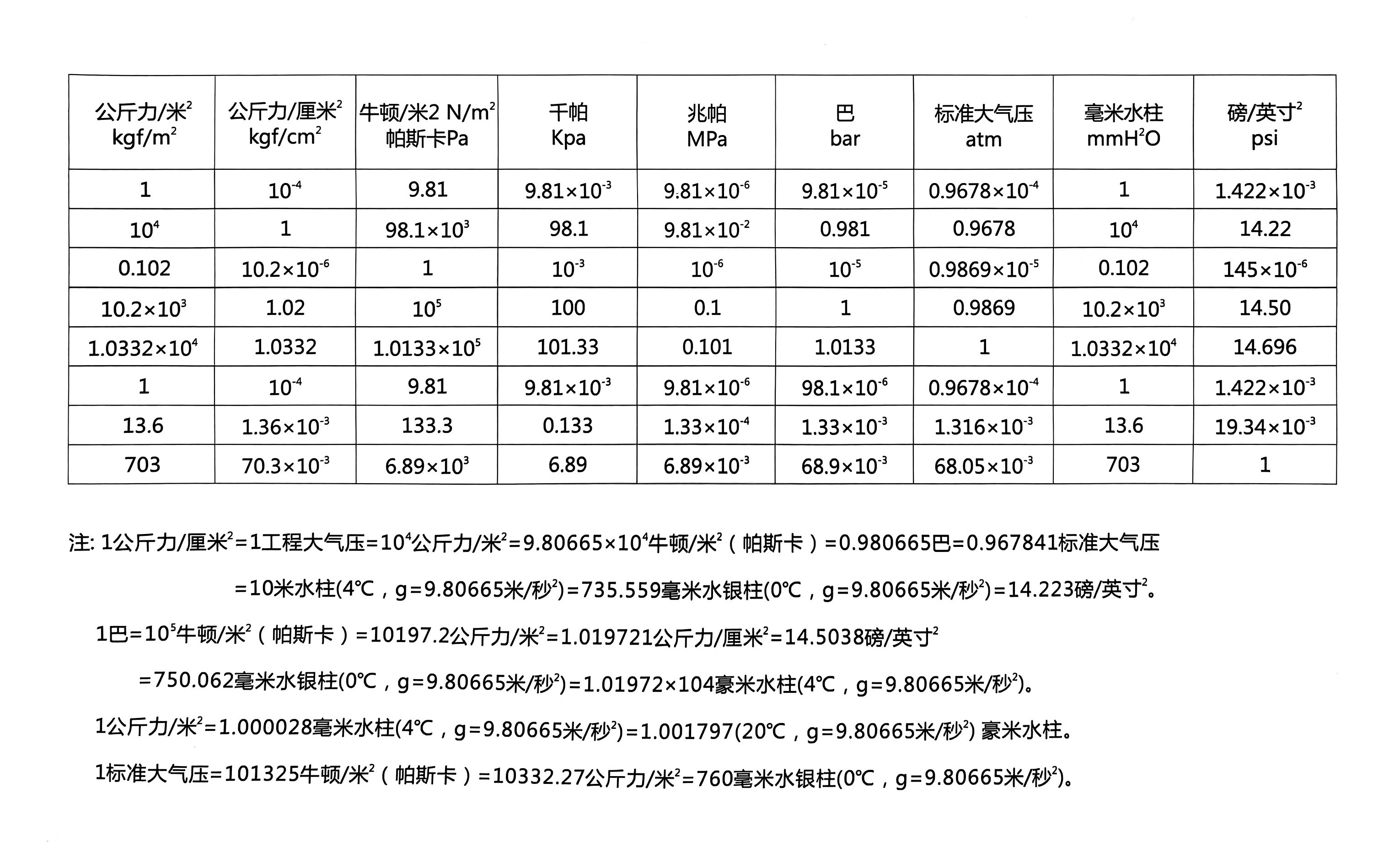

Pressure Unit Conversion Table

Reference Table for Corrosion Resistance of Materials in Contact with Medium

Product User Guide

Telephone

Technical Support

Sales Support

Address

B6-401 of New Generation Artificial Intelligence Industrial Park, No. 176 Biyuan 2nd Road, Xi 'an High-tech Zone

online message

All rights reserved©2024 Xi'an Senseus Sensor Co., Ltd.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

TEL:0086-029-81106070

Europe & Oceania:export@xian-sensors.com

Asia & Amercia:selina@xian-sensors.com

Whatsapp:18092690661

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home